The next evolution in high-performance electronic connectors and terminals. Purpose-built for demanding applications such as electric vehicles (EVs) and under-the-hood systems, Vol-Conn ™ is engineered to deliver uncompromising performance where high-temperature, high-current, and stress relaxation over time and thermal cycling often challenge conventional solutions.

Many connector companies rely on standards to arrive at a current rating for a particular product. Take a conventional 0.250” x 0.032” [6.35mm x 0.81mm] tab as an example. Zierick offers many 250 tabs (250 as they are commonly called in-house and in NA, others like to call them faston tabs). Since Zierick’s faston tab range conforms to UL 310 [UL file no. E146208], and there is a standard within UL 310 that calls out for a temperature rise test to arrive at a particular current rating, it made perfect sense for Zierick and other manufacturers to piggy-back UL standards to determine maximum recommended current ratings, measure in amperes [amps].

Since 1919, Zierick Manufacturing Corporation has been providing innovative solutions to the challenges posed by complex interconnection requirements.

Taking Zierick’s p.n. 1021 (in which Zierick pioneered the stable-lok ™ feature to enhance lateral strength when assembled to the PCB) we say the part has a current rating of 20 amps. And it does. As long as you understand that the test behind the ampere number is based on a temperature rise of 30 Degrees Centigrade above ambient. Say the ambient or room temperature at time of test is 20 degrees C, as the current going through p.n. 1021 is increased and it heats up (the higher the current, the more heat is generated), the test finally concludes when 50 degrees C is reached.

But these days, as Board Designers and Engineers know, 50 degrees isn’t much at all. Not when you consider that traditional under the hood temperatures in vehicles (particularly ICE) is much higher. And now the higher current demands of anciliary devices, pump motor control boards that need to get that head of liquid up to taller skyscrapers, and all sorts of electronics need to co-exist in a more demanding world.

Say we decide to run PN 1021 to 100 degrees C. That will result in a higher amperage rating. No problem, right ? After all, p.n. 1021 is a flat tab, there are no spring members and stress relaxation is not a problem… But, what about the receptacle that mates with p.n. 1021. Zierick p.n. 1237 can mate with p.n. 1021. Say p.n. 1021 is on the motor side of an application and p.n. 1237 is on the control board. Now we have a system, no longer a single part. And now the weakest link will most likely be the 1237 receptacle, since it has a spring member (or in the case of p.n. 1237 a dual spring member which can enhance reliability, but that’s another story). The higher the temperature the more likely the spring member is to relax over time and the greater the chance of failure.

So, the challenge in this case becomes material selection. This challenge resulted in Zierick releasing a high performance line for the entire product range that includes p.n. 1237, along with different plating options. Zierick p.n. 1237 becomes 1237HTA for example. And the results are interesting.

Introducing Zierick p.n. 1237HTA

Did we say 20 Amps earlier ?

What about **40 amps ?? (**subject to application testing)

MATING TERMINAL | 0.64 TO 0.81mm (.025 to .032”) thick tab |

MATING MISALIGNMENT | Lateral – ±0.30mm (.012”); Angular – ±10° |

MATERIAL | 0.41mm (.016”) thick STOL 76M |

FINISH | 100% Matte Tin over Copper |

CURRENT RATING | 40 A* |

CHEMICAL RESISTANCE w/Sn PLATING | Excellent – H2S, Cl2, NO2, NH3; Fair – Salt fog; Poor – SO2 |

* Not restricted by UL standards.

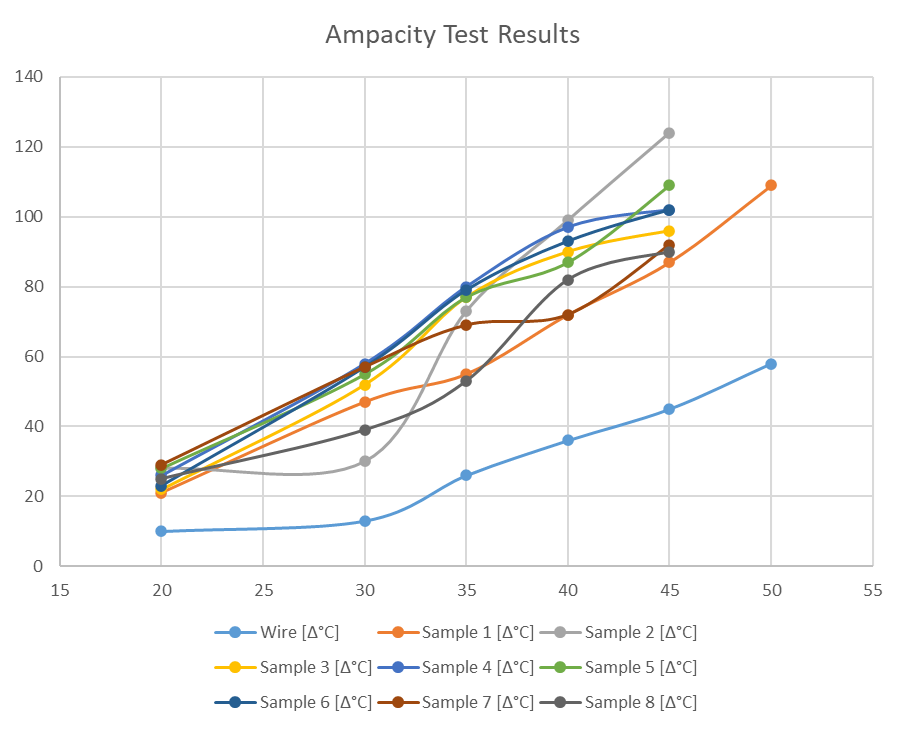

The ampacity test determines temperature rise versus current per EIA-364-70. Current was run through the receptacle until failure. Failure mode for all receptacles was failure of the solder joint.

The test was conducted in an open air environment with an ambient temperature of 18°C. SMT board had one ounce of copper. Heat-dissipation mechanisms were not used. 2-12 AWG (approx. 9 AWG) gasoline-resistant, stranded wires with nylon coating over PVC (THWN) were sistered per connection to a 6.4mmx0.81mm (.250”x.032”) tin-plated tab. Wire lead length from connector-to-connecter was approximately 152.4mm (6”) and ends had 152.4mm (6”) leads from the power supply.

Current [A] | Wire [Δ°C] | Sample 1 [Δ°C] | Sample 2 [Δ°C] | Sample 3 [Δ°C] | Sample 4 [Δ°C] | Sample 5 [Δ°C] | Sample 6 [Δ°C] | Sample 7 [Δ°C] | Sample 8 [Δ°C] |

20 | +10 | +21 | +28 | +22 | +26 | +28 | +23 | +29 | +25 |

30 | +13 | +47 | +30 | +52 | +58 | +55 | +57 | +57 | +39 |

35 | +26 | +55 | +73 | +77 | +80 | +77 | +79 | +69 | +53 |

40 | +36 | +72 | +99 | +90 | +97 | +87 | +93 | +72 | +82 |

45 | +45 | +87 | +124 | +96 | +102 | +109 | +102 | +92 | +90 |

50 | +58 | +109 | FAIL | FAIL | FAIL | FAIL | FAIL | FAIL | FAIL |

Failure Mode | – | None | Solder Joint Failure | Solder Joint Failure | Solder Joint Failure | Solder Joint Failure | Solder Joint Failure | Solder Joint Failure | Solder Joint Failure |

And this is the Vol-Conn ™ story. Every application is different and as more challenging applications emerge Zierick is re-imagining, re-testing and innovating discrete high performance PCB connection systems for today’s challenges.

Join us on the journey!